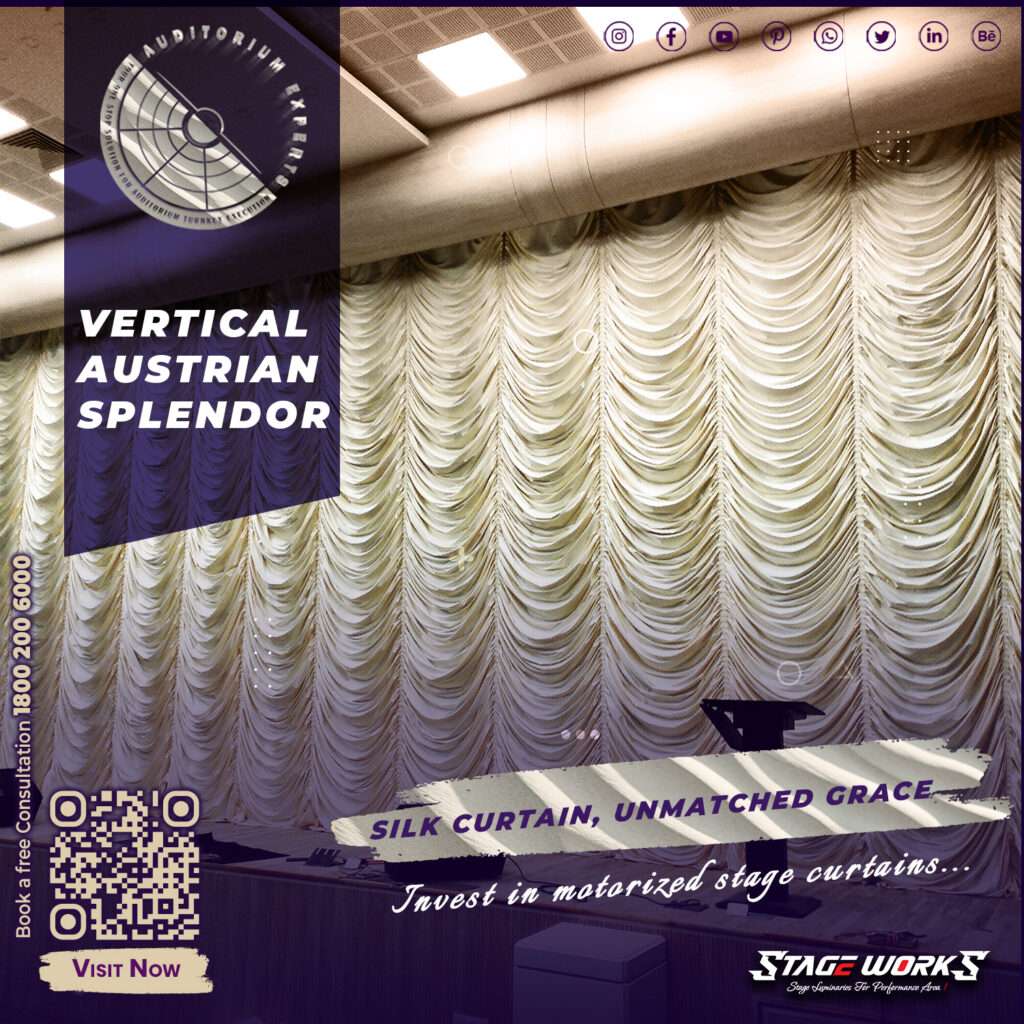

Engineered Balloon Vertical Uplift Stage front Curtains with Austrian Crushed Silk to the most theatrical openings: Engineered to a high standard designed

The supply, installation, testing, and commissioning of the motorized uplifting curtain system shall adhere strictly to all safety norms to ensure the protection of both performers and the audience. Skilled labor and specialized tailors will install the curtain to highlight the stage as the main attraction. The automatic motorized curtain, crafted from high-quality Long Crush fabric with a reflective look and luxurious fullness for an elegant visual effect, will be fabricated and installed as per architectural drawings under the supervision of the Engineer-in-Charge (EIC). The work will include all necessary tools, machinery, manpower, staging, and consumables, with the system featuring mild steel rail tracks for smooth operation, an upper and lower limit automatic stop mechanism, and a self-sustaining customized gearbox. Multi-cable drums will be configured to the project’s specific requirements, allowing the curtain to “fly in” and “fly out” seamlessly, ensuring efficient opening and closing. The setup will be customized to the stage, incorporating a mild steel pipe main shaft and mini rolling drum to suit site-specific conditions, ensuring proper weight distribution and smooth movement. The curtains will be gathered, rouged, hooked, enabling a functional vertical mechanism. The system will be supported by four bearings on a base frame attached to a 1.5″ MS square pipe, along with 40x40x5 mild steel angle suspenders forming a ladder-type frame to balance the weight effectively. The frame will be securely fixed on top of the mother grid, and the curtain’s movement will be powered by a 1-phase 1.0 HP motor (Godrej or Crompton Greaves) coupled with an engineered modified gearbox, complete with limit switches, coupling, pulleys, and 2mm steel wire mounted on an overhead iron base frame. The system will include air breaker contractors (L&T/Siemens), micro switches for auto-stop, and three push buttons for Up, Down, and Stop functions to ensure user-friendly control. The curtain will be complete with onsite fitting and stitching according to stage dimensions, with motor mounting on a “C” channel platform. Flame-retardant treatment as an optional service, subject to client preference for an additional charge. The shade and fabric sample will be subject to approval by the Engineer-in-Charge or the end user.

Curtain fabric : As physical sample approved by EIC or End-User

Fabrication material : TATA, JINDAL, APOLLO & KAMDHANU

Installation by : STAGE WORKS

Remember these points before making a purchase :

The proscenium front curtain is the centerpiece of any theater, serving as the audience’s first impression of the performance. As the most iconic and prestigious curtain, it plays a crucial role in setting the tone for the entire show. A well-crafted house curtain not only enhances the stage’s visual appeal but also reflects the venue’s unique identity, making it an essential feature for any auditorium.

Please find below the tentative pricing for the stage curtain installation:

Tentative Price: ₹1.78 Lacs /- INR per curtain

Curtain Size: covering 15ft to 20ft in height and 30ft to 40ft in width

Our technical teams will collaborate closely with you to manufacture curtains that are perfectly customized to your stage space!

We would like to clarify a few key points related to the execution of the work on-site:

Please note that transportation costs are to be borne by the client and will be calculated based on the actual location of the project.

Ladder Type Mild Steel (MS) Framework, designed to ensure proper weight distribution as part of our safety measures. This framework is specifically engineered to cater to the curtain load and other mechanical loads, ensuring structural integrity and durability, the cost of the MS framework will be charged extra on a per kilogram (KG) basis, depending on the site conditions and the weight of the materials used in constructing the MS frame. The final pricing will be determined after a thorough assessment of the site requirements and the overall weight required to construct the framework.

The final cost may vary after assessing the precise details.

Kindly consider this as a tentative estimate. We will provide a final quotation once all parameters are confirmed.

Accommodation for our installation team, either on-site or nearby, will be under your scope. This is crucial to ensure smooth operations and minimize delays during the execution of the project.

Ladde Type Frame will be charged per KG as per site condition and weight used to construct the frame Multi-cable drums

Scaffolding and other necessary support structures required for the safe and effective execution of the work will also be within your responsibility. Proper scaffolding is essential to ensure the safety and efficiency of our team during installation.

By coordinating these aspects in advance, we can ensure a seamless execution and timely completion of the project.