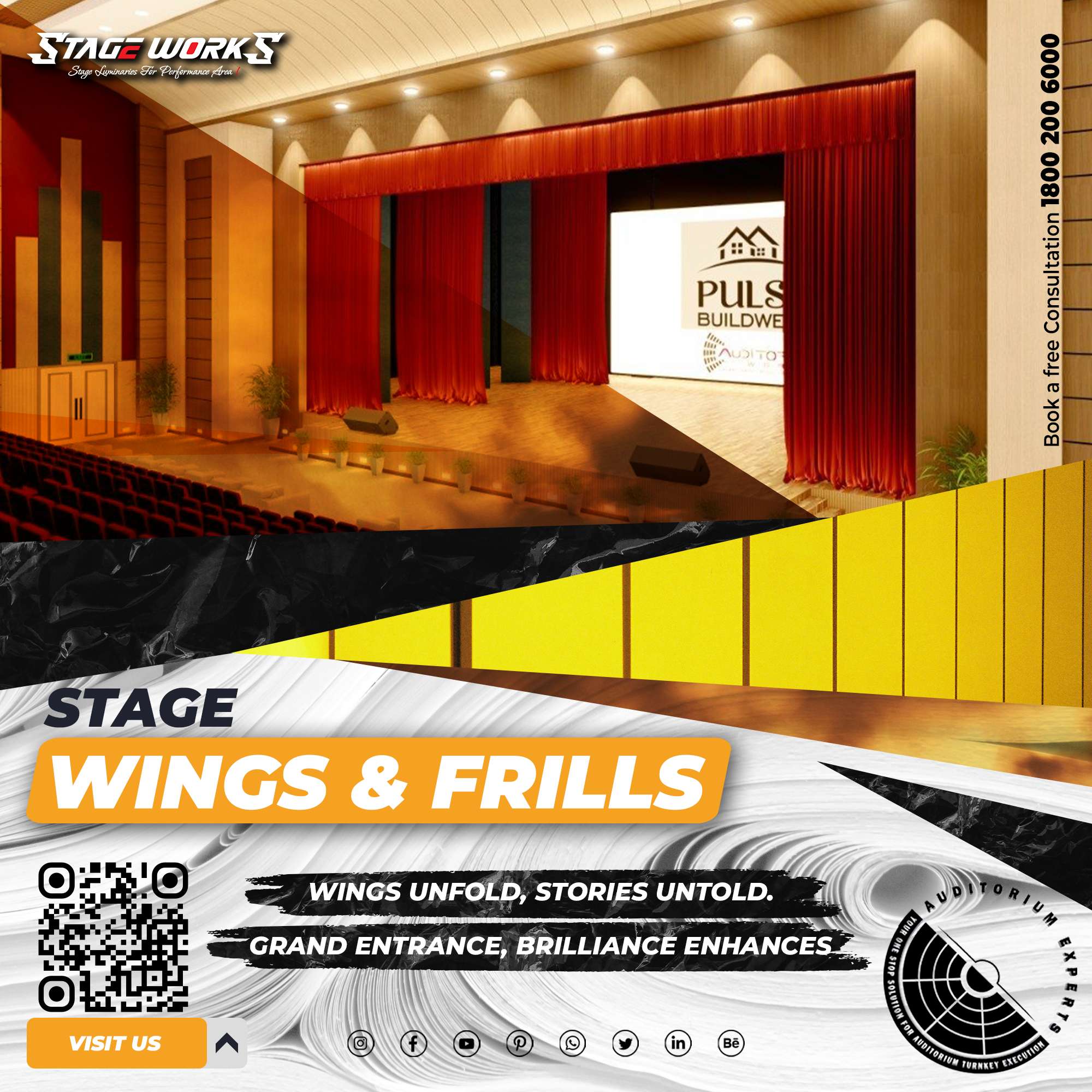

Installation of custom-made stage side wings, also known as flippers or side curtains, designed to effectively mask off-stage areas while providing strategic access points for performers, these stage leg curtains, placed along each side of the stage, serve a dual purpose of concealing the stage sides from the audience’s view and facilitating seamless performer entrances and exits from wing space to the main stage.

Providing and fixing of custom-made 360 Degree Revolving Stage Side Wings – flippers include the installation of specialized legs that conceal off-stage areas and create access points between sets for performers, the positioning and size of these curtains will be determined by the stage sightlines, ensuring optimal coverage and side masking, for increased functionality and versatility, they will be mounted on an overhead grid structure assembly to allow the curtains to rotate, Installation will be carried out by skilled labor and specialized on-site tailors for stitching, Stage Legs will be constructed of Mild Steel Rectangular Hollow Section Steel PIPES 50 X 25 MM (2 X 1 INCH) mounted on a pivoted rotatable bar, fixed with 6mm thick commercial plywood on both sides of wings and overlapped with 6mm Ethylene-vinyl acetate foam for enhanced durability, these legs will endure during performances, The framework will feature a rotatable assembly on roller-mounted MS barrel swing hinges, supported from the grid structure and concealed floor mount arrangement with fasteners on stage for 360-degree free rotation to adjust the wings as required as the main attraction. The side wings will be crafted from 100% heavy polyester Molfino fabric (450 GSM) to enhance acoustical properties and provide a reflective look with luxurious fullness. Installation will be carried out as per architectural drawings under the supervision of the Engineer-in-Charge (EIC), utilizing all necessary tools, machinery, manpower, staging, and consumables, including mild steel rail tracks for smooth operation.

Stage custom-made side wings also known as flippers or side curtains, legs hide off-stage areas and create access points between sets for performers, Leg curtains are placed down each side of stage to mask out the stage sides from audience view. Leg curtains also provide unseen entrance and exits channels for performers from wing space to main stage Their size and location is usually determined by the stage sight lines as these curtains work as stage side masking curtains and are designed to cover gaps. Since the legs will be exposed to “heavy on-stage traffic”; while not necessary, often times it is recommended for the legs to be lined to protect the face fabric, adding years of life to the curtain and also helping with opacity.

When used as stationary curtains, legs can be tied-up to a pipe batten. However, oftentimes there is a need to move these curtains on and off-stage, legs have to be hanged from overhead grid structure assembly. often used to conceal the stage’s backstage areas. This alternate setup increases functionality and versatility as the curtains can be traveled or rotated to provide a different stage ambiance and or to adjust the stage width. Installation will be performed by skilled labor and specialized tailors onside stitching fixed on 32mm Pivoted Rotatable Bar Fixed with 6mm thick commercial plywood on both sides overlapped pasting 6mm EVA Foam fixed on both side, Frame work with rotatable assembly on Roller MS barrel Swing Welding Farm Hinges top supported from grid structure, used for the 360 free rotation to arjust wings as required , it is designed to be fitted anc concealed below stage floorings and support from ceiling, emphasizing the stage as the main attraction. The curtains will be crafted from high-quality 100% heavy polyester Molfino fabric (450 GSM) to enhance acoustical properties, provide a reflective look, and offer luxurious fullness, work will be carried out as per architectural drawings under the supervision of the Engineer-in-Charge (EIC). The installation will involve all necessary tools, machinery, manpower, staging, and consumables, including mild steel rail tracks for smooth operation.